Inflatable paddleboard construction has revolutionised the world of stand-up paddleboarding. Unlike traditional solid boards, inflatable SUPs are crafted using advanced materials and technology. Such inventiveness results in boards that are lightweight, easily transportable and provide a stable, buoyant platform for a variety of activities, from fishing to yoga.

Let’s examine the materials and construction techniques that make iSUPs a favourite amongst paddling fans.

Materials and Techniques Used in Inflatable Paddleboard Construction

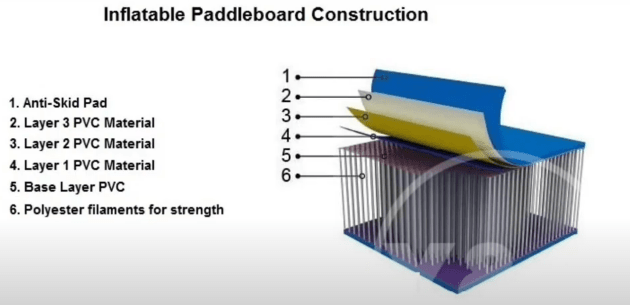

Drop-stitch technology: At the core of every iSUP is the drop-stitch technology. This innovative design involves two parallel layers of fabric connected by thousands of fine threads. When inflated, these threads pull tight, allowing the board to hold its shape and provide a firm surface akin to a traditional hardboard.

Layers and lamination: To enhance the board’s rigidity and durability, several layers of material are laminated together. This lamination process is crucial for providing the structural integrity needed for the iSUP to perform well in various water conditions.

PVC material – the protective outer layer: The primary material used in the construction of iSUPs is PVC (polyvinyl chloride). This durable plastic coating is applied to the top and bottom fabric sheets of the drop stitch core, creating a strong, puncture-resistant outer layer that can withstand the rigours of paddling.

Some of the most advanced iSUP models also incorporate sheets of carbon fibre within the PVC layers to add extra stiffness and stability.

Construction variants – single layer vs. fusion: The construction of inflatable paddleboards can vary, with some models having a single layer of PVC-coated fabric, while others use a fusion method.

Fusion construction involves two layers of fabric that are bonded together before the PVC coating is applied. This results in a board that is more rigid and robust than its single-layer counterparts, delivering better performance and longevity.

Rail bands and reinforcement strips: These are vital components in inflatable paddleboard construction. The rail bands, which are typically made from PVC material, wrap around the rails (sides) of the board, thereby joining the top and bottom layers and creating an airtight chamber. This ensures that the board will maintain its shape and firmness when inflated.

Manufacturers often use multiple layers of rail bands to enhance stiffness and durability.

Reinforcement strips, often made from carbon fibre or by adding extra PVC layers, are added to further strengthen the board. These strips are strategically placed along the rails and other high-stress areas to provide extra stiffness and to prevent deformity when pressure is applied.

In summary, the materials and construction of an iSUP are designed to provide a balance of flexibility and firmness, ensuring that you can enjoy the benefits of a stable, buoyant platform without the bulk and weight of a solid paddleboard.

With diligent care and good inflatable paddleboard maintenance, a board made from these high-quality materials can offer years of paddling pleasure.

If you are interested in purchasing a new iSUP, Confluence Outdoor are known for their premium quality stand-up paddleboards. They offer a range of iSUPs suitable for various activities and skill levels.

Pin this image on Pinterest: